The ZF 6HP transmission, a hallmark of engineering excellence, is renowned for its smooth shifting and robust performance. Developed by ZF Friedrichshafen AG, this transmission has become a staple in various high-performance vehicles, delivering exceptional driving dynamics. Understanding the solenoid diagram of the ZF 6HP Generation 2 transmission is crucial for anyone involved in automotive repair or maintenance, as solenoids play a pivotal role in its operation.

Importance of the Solenoid in the ZF 6HP Transmission

Solenoids in the ZF 6HP transmission control hydraulic pressure and fluid flow, facilitating precise gear shifts. A well-maintained solenoid system ensures optimal transmission performance, enhancing the overall driving experience. By delving into the ZF 6HP Generation 2 solenoid diagram, we can better appreciate its intricacies and learn how to troubleshoot common issues effectively.

Understanding the ZF 6HP Transmission

What is the ZF 6HP Transmission?

The ZF 6HP transmission is a six-speed automatic transmission used in a variety of high-performance and luxury vehicles. It is known for its advanced engineering, delivering seamless gear transitions and improved fuel efficiency. This transmission’s innovative design includes multiple solenoids that work together to control the flow of transmission fluid, making it a highly efficient system.

Key Features of ZF 6HP Generation 2

The Generation 2 of the ZF 6HP transmission introduced several enhancements over its predecessor. Key features include faster shift times, improved fuel efficiency, and increased torque capacity. Additionally, this generation boasts advanced electronic controls and a more refined hydraulic system, which contributes to smoother and more precise gear changes. These improvements make the ZF 6HP Generation 2 a preferred choice for many modern vehicles.

Applications of ZF 6HP Transmission

The ZF 6HP transmission is widely used in various vehicles, including luxury sedans, SUVs, and sports cars. Brands such as BMW, Audi, Jaguar, and Land Rover have all incorporated this transmission into their models due to its reliability and performance benefits. Its versatility and adaptability to different driving conditions make it a favored option among automakers and enthusiasts alike.

The Role of Solenoids in ZF 6HP Transmissions

What are Solenoids?

Solenoids are electromechanical devices that convert electrical energy into mechanical motion. In the context of automatic transmissions, solenoids control the flow of hydraulic fluid to various components, enabling precise gear shifts. These small but powerful devices are essential for the smooth operation of modern automatic transmissions, including the ZF 6HP.

Function of Solenoids in Automatic Transmissions

In automatic transmissions, solenoids act as gatekeepers, regulating the flow of transmission fluid to different parts of the system. They are activated by the transmission control module (TCM), which sends electrical signals to the solenoids based on driving conditions and input from various sensors. This coordination ensures that gears shift at the right time, providing a smooth and efficient driving experience.

Importance of Solenoids in the ZF 6HP Transmission

The solenoids in the ZF 6HP transmission are critical for its performance and reliability. They control key functions such as pressure regulation, shift timing, and torque converter engagement. A malfunctioning solenoid can lead to issues like harsh shifts, delayed engagement, or even transmission failure. Therefore, understanding and maintaining these solenoids is vital for the longevity and efficiency of the ZF 6HP transmission.

Detailed Overview of the ZF 6HP Generation 2 Solenoid Diagram

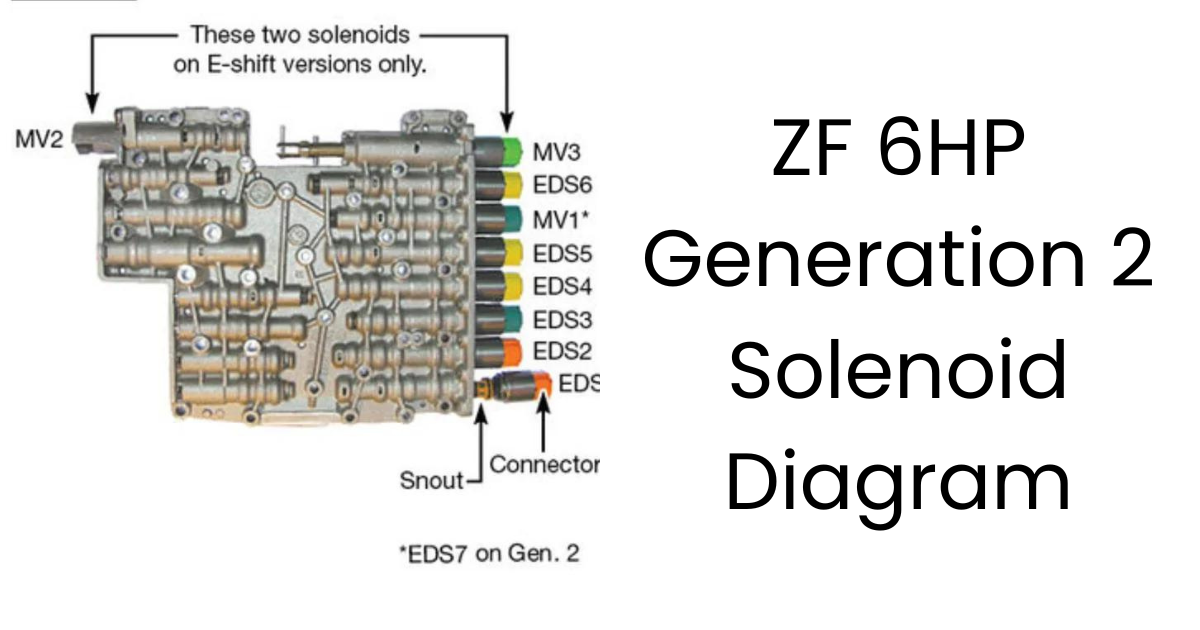

Introduction to the Solenoid Diagram

The ZF 6HP Generation 2 solenoid diagram is a visual representation of the transmission’s solenoid configuration. It outlines the placement and function of each solenoid within the transmission, providing a clear roadmap for diagnostics and repairs. This diagram is an invaluable tool for technicians and automotive enthusiasts, aiding in the accurate identification and resolution of transmission issues.

Components of the Solenoid Diagram

The solenoid diagram for the ZF 6HP Generation 2 includes several key components, each playing a distinct role in the transmission’s operation. These components typically include pressure control solenoids, shift solenoids, the torque converter clutch (TCC) solenoid, and the line pressure solenoid. Each of these solenoids is strategically placed to manage specific functions, ensuring optimal transmission performance.

Reading the Solenoid Diagram

Reading the solenoid diagram involves understanding the layout and connections of the various solenoids. The diagram provides detailed information on the wiring and fluid pathways, helping technicians diagnose and address issues efficiently. By familiarizing themselves with the diagram, technicians can quickly pinpoint problem areas and implement effective solutions, minimizing downtime and repair costs.

Components of the ZF 6HP Generation 2 Solenoid

Pressure Control Solenoids

Pressure control solenoids regulate the hydraulic pressure within the transmission. They ensure that the right amount of pressure is applied to the clutches and bands, facilitating smooth and timely gear shifts. These solenoids are crucial for maintaining optimal transmission performance, as incorrect pressure can lead to erratic shifts and potential transmission damage.

Shift Solenoids

Shift solenoids are responsible for controlling the engagement and disengagement of gears. They receive signals from the transmission control module (TCM) and manage the flow of hydraulic fluid to the appropriate components. Proper functioning of shift solenoids is essential for smooth gear transitions and overall transmission health.

Torque Converter Clutch (TCC) Solenoid

The torque converter clutch (TCC) solenoid controls the engagement of the torque converter clutch, which locks the torque converter to improve fuel efficiency and reduce heat generation. The TCC solenoid plays a vital role in ensuring optimal power transfer from the engine to the transmission, enhancing overall vehicle performance.

Line Pressure Solenoid

The line pressure solenoid manages the overall hydraulic pressure within the transmission system. It adjusts the pressure based on driving conditions, ensuring that the transmission operates efficiently and smoothly. Proper functioning of the line pressure solenoid is critical for maintaining the balance and performance of the entire transmission system.

Common Issues with ZF 6HP Generation 2 Solenoids

Symptoms of Faulty Solenoids

Faulty solenoids can manifest in various ways, impacting the transmission’s performance. Common symptoms include delayed or harsh gear shifts, transmission slipping, and unexpected downshifts. Additionally, drivers may notice the transmission going into limp mode, where it remains in a single gear to prevent further damage. Recognizing these symptoms early can help prevent more severe transmission issues.

Causes of Solenoid Failure

Several factors can contribute to solenoid failure in the ZF 6HP transmission. These include wear and tear from regular use, contamination of the transmission fluid, and electrical issues such as short circuits or damaged wiring. Understanding the root causes of solenoid failure can aid in preventive maintenance and extend the life of the transmission.

Diagnosing Solenoid Problems

Diagnosing solenoid problems involves a combination of visual inspections, electrical testing, and reading diagnostic trouble codes (DTCs). Technicians use specialized tools to check the continuity and resistance of the solenoids, ensuring they are within the specified range. Additionally, inspecting the transmission fluid for signs of contamination can provide clues about potential solenoid issues.

Maintenance and Troubleshooting

Routine Maintenance Tips

Regular maintenance is essential for keeping the ZF 6HP transmission and its solenoids in optimal condition. Key maintenance tips include regular transmission fluid changes, using the recommended fluid type, and inspecting the transmission for leaks. Additionally, following the manufacturer’s service schedule can help prevent solenoid issues and extend the transmission’s lifespan.

How to Test Solenoids

Testing solenoids involves checking their electrical and mechanical functions. Technicians use a multimeter to measure the resistance and continuity of the solenoids, ensuring they meet the manufacturer’s specifications. Additionally, a scan tool can read diagnostic trouble codes and monitor solenoid operation in real time, helping to identify any discrepancies or malfunctions.

Troubleshooting Common Issues

Troubleshooting solenoid issues requires a systematic approach, starting with identifying the symptoms and conducting a thorough inspection. Technicians should check for any visible damage or wear, test the electrical connections, and verify the functionality of the solenoids. In some cases, replacing the transmission fluid and filter can resolve minor issues and restore solenoid performance.

Replacing ZF 6HP Generation 2 Solenoids

Tools Needed for Replacement

Replacing solenoids in the ZF 6HP transmission requires specific tools, including a multimeter, a scan tool, and basic hand tools like wrenches and screwdrivers. Additionally, having access to the transmission’s solenoid diagram and service manual can provide valuable guidance during the replacement process. Ensuring the right tools are on hand can make the replacement procedure more efficient and successful.

Step-by-Step Replacement Guide

Replacing the solenoids involves several steps:

- Preparation: Disconnect the battery and lift the vehicle to access the transmission.

- Drain the Transmission Fluid: Remove the transmission pan and drain the fluid.

- Remove the Valve Body: Carefully detach the valve body to access the solenoids.

- Replace the Solenoids: Disconnect and remove the faulty solenoids, then install the new ones.

- Reassemble: Reinstall the valve body, refill the transmission with fluid, and reconnect the battery.

Following these steps methodically ensures a successful solenoid replacement.

Post-Replacement Testing

After replacing the solenoids, it’s crucial to conduct thorough testing to ensure everything is functioning correctly. This includes checking for leaks, verifying that the transmission fluid level is correct, and using a scan tool to clear any diagnostic trouble codes. Taking the vehicle for a test drive can confirm that the transmission shifts smoothly and that the solenoids are operating as intended.

FAQs about ZF 6HP Generation 2 Solenoids

Q1: How long do ZF 6HP solenoids last?

Ans: The lifespan of ZF 6HP solenoids can vary depending on driving conditions, maintenance practices, and overall transmission health. On average, solenoids can last between 100,000 to 150,000 miles. Regular maintenance, including timely transmission fluid changes, can extend their lifespan and ensure reliable performance.

Q2: Can solenoids be repaired or only replaced?

Ans: In most cases, solenoids are replaced rather than repaired. While some minor issues like electrical connection problems can be fixed, internal solenoid failures usually require replacement. Using high-quality replacement solenoids and following proper installation procedures can restore transmission performance and reliability.

Q3: What are the costs associated with solenoid replacement?

Ans: The cost of solenoid replacement can vary based on several factors, including the specific solenoids being replaced, labor costs, and the vehicle make and model. On average, solenoid replacement can range from $200 to $500 per solenoid, including labor. Obtaining quotes from multiple repair shops and using OEM (Original Equipment Manufacturer) parts can help manage costs.

Conclusion

Understanding the ZF 6HP Generation 2 solenoid diagram is essential for maintaining and repairing this advanced transmission system. The solenoids play a crucial role in regulating hydraulic pressure and fluid flow, ensuring smooth and efficient gear shifts. Recognizing symptoms of faulty solenoids, conducting regular maintenance, and following proper diagnostic and replacement procedures can help keep the ZF 6HP transmission in optimal condition.